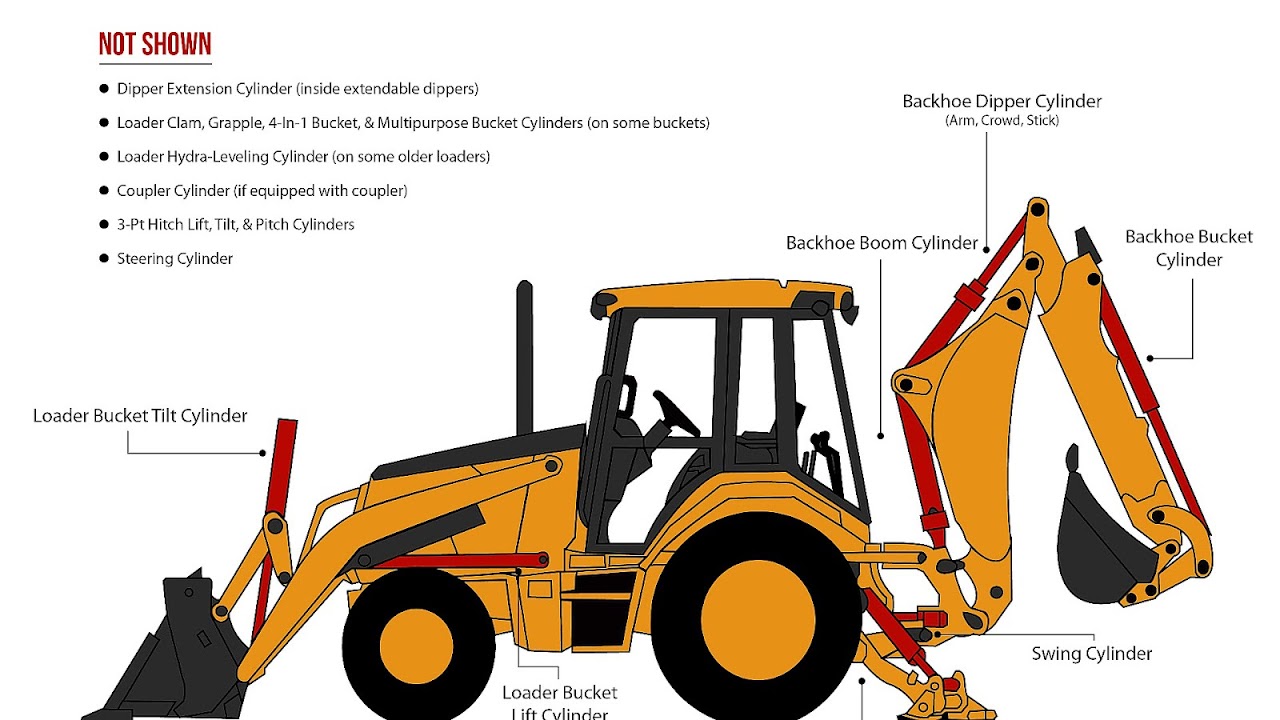

A backhoe, also called a rear actor or back actor, is a piece of excavating equipment or digger consisting of a digging bucket on the end of a two-part articulated arm. They are typically mounted on the back of a tractor or front loader, the latter forming a 'backhoe loader' (colloquially known as a JCB in Ireland and UK). The section of the arm closest to the vehicle is known as the boom, and the section which carries the bucket is known as the dipper or dipper-stick, terms derived from steam shovels). The boom is generally attached to the vehicle through a pivot known as the king-post, which allows the arm to pivot left and right, usually through a total of around 180-200 degrees.

Maps, Directions, and Place Reviews

Characteristics

The name "backhoe" refers to the action of the shovel, not its location on the vehicle: a backhoe digs by drawing earth backwards, rather than lifting it with a forward motion like a man shovelling, a steam shovel or a bulldozer. Confusingly, the buckets on some backhoes may be reconfigured facing forward, making them "hoes". However they are not as effective in that orientation, since the dimensions of the various components are optimized for backhoeing. Most backhoes are at their strongest curling the bucket, with the dipper arm next most powerful, and boom movements the least powerful.

A backhoe loader is a tractor-like vehicle with a backhoe at one end, a front loader on the other and a swivelling seat to position the operator facing whichever he is using at the time. In North America, this arrangement is often referred to as simply a backhoe or, when on a chassis originally derived from farm tractors, a tractor loader backhoe (TLB). To differentiate, a backhoe on its own dedicated chassis may then be referred to as an "excavator".

Backhoe loaders can be designed and manufactured from the start as such, or can be the result of a farm tractor equipped with a front end loader (FEL) and rear backhoe. Though similar looking, the purpose-designed backhoe loaders are much stronger, with the farm variation unsuitable for heavy work. The farm variation also requires that the operator switch seats from sitting in front of the backhoe controls to the tractor seat in order to reposition the equipment while digging, and this often slows down the digging process.

With the advent of hydraulic powered attachments such as a tiltrotator, breaker, a grapple or an auger, the backhoe is frequently used in many applications other than excavation and with the tiltrotator attachment, serves as an effective tool carrier. Many backhoes feature quick coupler (quick-attach) mounting systems for simplified attachment mounting, dramatically increasing the machine's utilization on the job site. Backhoes are usually employed together with loaders and bulldozers. Excavators that use a backhoe are sometimes called "trackhoes" by people who do not realize the name is due to the action of the bucket, not its location on a backhoe loader.

Backhoe loaders are general-purpose tools, and are being displaced to some extent by multiple specialist tools like the excavator and the speciality front end loader, especially with the rise of the mini-excavator. On many job sites which would have previously seen a backhoe used, a skidsteer (colloquially often called a Bobcat after the most well known manufacturer and inventor of the category) and a mini excavator will be used in conjunction to fill the backhoe's role. However, backhoes still are in general use.

Sometimes a backhoe bucket is reversed to work in a power shovel configuration. This is generally when loading from a large stockpile, for picking up or filling material next to walls, to increase the reach of the machine, or working around obstacles such as pipes.

Sometimes a backhoe arm is used as a crane, by slinging the lifted object from the support linkages behind the scoop (advisably not from the teeth).

How Much Can A Backhoe Lift Video

Thumb

The backhoe's scoop may have a metal bar called a "thumb" hinged to the scoop. It grips against the scoop like a human thumb to pick up objects. Some types can lie back against the backhoe arm when not needed.

Origins

Early development of hydraulic systems for what would become the backhoe loader proceeded in parallel in the US and the UK. The invention of the first backhoe swing frame was developed in July 1947 by Vaino J. Holopainen (pronounced "Waino") and Roy E. Handy, Jr. (thus the company name "Wain-Roy"), and assigned to Wain-Roy Corporation of Hubbardston, Massachusetts, United States. In July 1948, patent # 2,698,697 was filed by Vaino J. Holopainen. The swing frame breakthrough allowed the hydraulic digging arm to swing to the side to dump the bucket. This patent also included the invention of the out-rigger bar, and high flow control. In April 1948 Wain-Roy Corporation sold the very first all hydraulic backhoe, mounted to a Ford Model 8N tractor, to the Connecticut Light and Power Company. Wain-Roy made 24 units in 1948. Wain-Roy also made them for Sherman Products of Royal Oak, Michigan, and Ford. Approximately 7000 Wain-Roy Backhoes were manufactured and sold between the fall of 1948 and early 1954, mainly through Ford dealers.

In the same year, 1948, JCB launched the first European hydraulic loader, and followed that in 1953 with a backhoe with a 180° slew, fitted to a tractor. Then in 1957, while Case produced the first "integrated" Tractor Loader Backhoe in the US (whereby all the components were manufactured and warranted by the same manufacturer), JCB introduced the first dedicated backhoe loader (whereby the loader and backhoe were permanently attached to the chassis, allowing them to be more robust, rather than being demountable accessories for an agricultural tractor). In 1965, they would follow this with the world's first 360° excavator.

The patent for the first reversible seat was developed at Wain-Roy by Carroll Arnold and Vaino Holopainen and then filed by Vaino under patent #2,784,768, and in June 1954, Vaino filed patent # 2,781,927 for individually controlled outriggers. John S. Pilch of Ware Machine Works, Ware, MA, developed the first 4-bar linkage to achieve greater bucket digging and dumping rotation. Pilch filed for patent #2,678,741 in September 1950. The 4-bar linkages were also used on the Wain-Roy backhoes after 1954.

The first hydraulic wheel loader was invented by Frank G. Hough in the mid-1940s under patents 2,782,946 and 2,726,778. The first Tractor Loader Backhoe was a Wain-Roy backhoe mounted to a Frank G. Hough model "HE" in 1952 in Holden, Massachusetts, US, for the Holden Water Department. The F.G. Hough Company was a subsidiary of the International Harvester Company. By early 1954, two Hough "Payloader" model wheel loaders, the HE and the HF, were available with Wain-Roy backhoes. In 1954 Wain-Roy Corporation got a deal with IH for the Hough TLB full-scale production on several other models of Hough loaders.

In 1960 Vaino Holopainen was introduced as "Mr. Backhoe" to Henry Ford II. Wain-Roy continued to produce them for Ford until 1963 when Ford made their own and Wain-Roy could not compete with such a large company after that. Wain-Roy Corporation bought the AC Anderson Company and then the company suffered.

In 1964 Elton B. Long of the J.I. Case Corporation filed a patent #3,249,244 for the first extendible boom. Patent #3,273,729 was filed in January 1965 by Vaino J. Holopainen for the first hydraulic thumb.

Although Wain-Roy Corporation no longer exists, the Wain Roy product line of backhoe attachments and couplers is still available through the Woods Equipment Company of Rockford, Illinois, US.

Because of the long-time predominance of the JCB marque in the United Kingdom and Ireland, it has become a genericized trademark there, and backhoe-equipped diggers are commonly called JCBs, while the term "backhoe" as an excavator component is almost unknown to the general public in this context. The founder of the JCB company, Joseph Cyril Bamford, holds the honour of being the only non-American in the U.S. construction industry's hall of fame.

The American company Hy-Dynamic, a division of Bucyrus-Erie, introduced the second purpose-built American-made backhoe loader in 1959, the Dynahoe Model A. It offered a 14,000 lb. operating weight, 14-foot dig depth, and was powered by either a 65 hp Continental flat-head "Red Seal" 6-cylinder gasoline engine, or starting in 1961, a Detroit Diesel 353 diesel engine. The gasoline engine was phased out in 1964, with only diesel-powered units produced from that point on. The company marketed the Dynahoe as the only purpose-built backhoe-loader; previously all American backhoes were merely farm tractors fitted with front loader and rear backhoe attachments. The Dynahoe was built very robustly from the ground up with heavy excavation in mind. Production of the Dynahoe continued into the early 1990s culminating in the model Dynahoe 200-4, with a 36,000 lb. operating weight, 4-wheel drive, and a 20-foot dig depth. Production ceased with demand wavering in favor of more modern and versatile excavator type machines becoming more cost effective, and productive. Many of the original Dynahoe Model A's are still in use to this day.

The first, and much more popular Case Corporation introduced their backhoes in 1957. The design of the Case backhoes, from the straight arm boom assembly, to the "Extendahoe" design, which can extend the dipper from four to eight feet longer, are all registered with the U.S. Patent Office, along with the chassis design. JCB also brought their range of backhoe loaders, tractors and other products, to the North American market in 1960.

Backhoe fade

Backhoe fade or JCB fade is a humorous term coined by the telecommunications industry, referring to the accidental damage or complete severing of a communications cable by a backhoe or similar construction activity.

The term is a play on other types of signal loss, especially on wireless networks. Most of these cause a reduction in the signal, such as Rain Fade. A cable subjected to "JCB Fade" is instead a sudden and initially inexplicable loss of signal experienced when a cable is accidentally dug up and damaged or cut.

Depending on the particular cable destroyed, service may be interrupted to just a few customers or, for a large fiber optic cable, millions of customers across an entire continent.

Notable manufacturers

- Case CE (Subsidiary of CNH)

- Caterpillar Inc.

- Çukurova

- Deere & Company

- Ford Motor Company

- Hitachi Construction Machinery (Europe) (Subsidiary of Hitachi Construction Machinery)

- Hydrema

- JCB

- Komatsu

- Kubota

- LiuGong

- Massey Ferguson (Subsidiary of AGCO)

- New Holland Construction

- Terex

- Volvo Construction Equipment (Subsidiary of Volvo)

- XCMG

Source of the article : Wikipedia

EmoticonEmoticon